What is inventory management?

Inventory management for field service businesses involves keeping track of products, inventory, orders, and fulfilment. Since field service companies have so many items to manage across a range of locations, it’s essential to know who has them, where they are, and when to order more.

When it comes to running a successful field service company, managing streamlined inventory is just as important for your cash flow as it is for delighting customers. Inventory management technology can simplify this tricky process and help you keep on top of your stock, equipment, and assets.

Why is stock control important?

According to a recent study, 43% of small businesses fail to track their inventory effectively, which loses them a significant amount of money each year.

Companies that use paper-based sign in and sign-out sheets to manage stock levels run the risk that engineers will forget to fill them out from time to time. Engineers’ handwriting may be illegible, which makes it difficult for the back-office team to decipher what they’ve written. Some engineers may take too many items and store them in their vans for a different project, instead of putting them back.

It's easy to see how the numbers can stop adding up. Although slight inconsistencies in stock levels may not seem that damaging, they can cause challenges for your organisation in the long run.

Without accurate and reliable data, you won’t have full visibility over your equipment and assets. As a result, you could end up spending more money than you need to, reducing first-time fix rates, increasing downtime and losing high-value items.

Companies that have access to inventory management tools benefit from:

1. FEWER EQUIPMENT LOSSES

Manual check-out and check-in sheets to keep track of your equipment don’t always work and are inherently error-prone. In fact, human error is the leading problem for 46% of businesses when it comes to accurately reporting on assets.

Without an efficient inventory management system, equipment can go missing and there’s no exact way of tracking what happened to it. Not only will lost equipment likely stall other projects, but replacements can be pricey.

When you digitise your asset management approach, you can create a detailed register of equipment and other vital assets, maintain a record of fitted parts, track item movements and include serial numbers, barcodes or QR codes on the stock. Your engineers can then check inventory in and out directly from their mobile devices, and you will have better visibility over your valuable equipment.

2. IMPROVED FINANCES

Did you know, 80% of equipment maintenance is reactive? Studies show that most field service businesses only maintain their assets when they break down or need immediate repair. However, proactive conservation of stock equipment and assets is less expensive in the long run and prevents disruptions to your workflow.

It can be challenging to schedule regular maintenance when you don’t have full visibility over your equipment and data isn’t being recorded properly. Broken equipment can have a knock-on effect, leaving your workers without the tools or materials they need to carry out jobs. Aside from being a major inconvenience, halted projects will destroy your bottom line.

With a cloud-based asset and stock management tool, you can raise cases directly against your equipment for more efficient maintenance. Your engineers will always have the right gear for the job, and you won’t have to worry about something breaking down unexpectedly.

You can use the accurate and reliable data that the system updates in real-time to make the most of your assets. Assign stock and equipment directly to jobs for seamless check-in and check-outs, maximising efficiency, profit and first-time fix rates.

3. PROCESSES THAT GROW AS THE BUSINESS DOES

Unfortunately, inaccurate asset management reporting results in an estimated $1.1 trillion loss for businesses globally. Although manual processes may work when you don’t have many items to consider, it doesn’t provide you with much room to scale your operations. Consequently, you may struggle to monitor all your stock as your business grows.

Using asset and stock management software, you’ll have the most accurate and reliable data to hand, which allows you to digitally keep track of all your assets, regardless of quantity or location. Subsequently, you’ll never have an issue with over-ordering stock or not having the suitable materials or equipment available for scheduled jobs.

With an easy-to-use platform in place, you can also maintain your team’s productivity by eliminating burdensome processes and freeing up their time to focus on other tasks that contribute directly to business growth.

Ways poor inventory management reduces profits

1. STOCK LEVEL ISSUES

When engineers inadvertently take more items than they need, it will cause your stock levels to appear lower than they really are. Inconsistent inventory quantities and an inability to track what happened to each item will lead you to order more stock or replacement tools than you need, which eats into your profits.

2. PROJECT DELAYS

On the opposite end of the spectrum, human error may lead you to believe that you have plenty of tools and equipment for your customers’ appointments when you don’t. As a result, you’ll have to put work on hold, which is inconvenient for your customers, and causes scheduling and financial issues on your end. In a worst-case scenario, dissatisfied customers could take their business elsewhere.

3. LOWER FIRST-TIME FIX RATES

For field service businesses, having a high first-time fix rate is essential. Companies that achieve a first-time fix rate of over 70% enjoy an 86% customer retention rate, so you must ensure that your engineers always have the right tools and equipment to complete the job during the first appointment. However, inconsistent inventory levels could cause you to be unprepared for scheduled work.

The best ways to streamline inventory management today

In a nutshell, harnessing the power of modern technology is one of the best ways to manage your inventory effectively. Long gone are the days when you need to rely on error-prone sign in and sign out sheets or slow legacy systems to get the job done.

Not only can you eliminate the inefficiencies caused by outdated inventory management methods, but you can also enhance the services you’re able to provide and boost your bottom line simultaneously.

Field service management platforms are specifically designed to help you run every aspect of your business — from accepting appointments to inventory management and invoicing. So, using modern technology to handle your stock, equipment, and assets can improve your efficiency and profits.

1. ASSIGN TOOLS, EQUIPMENT AND STOCK DIRECTLY TO JOBS

According to data from Aberdeen Strategy & Research, 29% of failed first-time fixes are caused by parts being unavailable, making it the most common obstacle. Fortunately, when you use a job management platform to handle your inventory, you’ll have complete visibility over what stock you have, wherever it is.

Using the accurate data — which with some systems updates in real-time — you can allocate tools, equipment, parts and vehicles directly to customers’ appointments based on their unique requirements. Your engineers won’t have to worry about whether they have the right gear and, instead, they can focus on doing what they do best.

Ultimately, not only will your engineers be able to visit more customers per day, but you’ll find that your customer satisfaction and retention levels will rise, leading to repeat custom. Win-win!

2. ADD BARCODES, SERIAL NUMBERS OR QR CODES TO EACH ITEM

Barcodes, serial numbers and QR codes are incredibly helpful for inventory management. By adding a code or number to each item in your inventory, you’ll be able to keep track of everything at the click of a button.

If someone does takes extra equipment by mistake or you notice something is missing, you can find out what happened to it and who has it in their possession.

With our field service management platform, your engineers can use the mobile app to scan items in and out of storage with ease. While digital processes lower the risk of engineers forgetting to sign gear in and out, they also enable your back-office team to live track individual items without needing to scan through pages of handwritten notes.

3. CREATE LOW STOCK ALERTS

You’ll never have to worry about having enough stock. All you need to do is set your minimum stock levels and you’ll receive an alert whenever it’s time to replenish your warehouse.

As well as saving time and reducing the amount of paperwork, a digitised inventory will save you money since it takes every item — including those in your engineers’ vans — into consideration. There’s no risk of a false alert, which means you won’t be spending money on replacements when you don’t need to.

4. CREATE A COMPREHENSIVE WORK RECORD

When you need to look at work history and check where specific parts have been used, you can’t rely on paperwork, error-prone spreadsheets, and legacy systems. It’s likely to create confusion, and your engineers may needlessly end up replacing parts they replaced during the previous appointment.

Field service management software provides a comprehensive, accurate, and detailed record of everything your engineers did during every appointment. Using their mobile devices, engineers can add the information to the platform and capture photographs of the work they carried out.

Should you need to revisit a problem, you won’t end up using parts that you don’t need to. And aside from saving you money, a well-kept record will also enable your engineers to work more rapidly, impressing your customers and boosting your bottom line.

3 top benefits of managing your inventory with technology

As well as making everyday life easier, the right technology has a huge benefit to your business over the long-term.

1. REDUCE THE CHANCE OF HUMAN ERROR

📣 Did you know that human error is the leading issue for just under half (46%) of warehouses?

Many businesses struggle with large losses in inventory, as poor reporting leads to inaccurate stock levels. With job management technology, managing your stock needn’t be a logistical nightmare. As we mentioned earlier, your engineers can simply sign tools and parts in and out of storage from their mobile devices, which enables your back-office team to track each item.

Having full, real-time visibility over your valuable assets means that there will never be inconsistencies in stock levels and, therefore, you’ll always have the items you need to get the job done perfectly the first time.

2. STRENGTHEN YOUR FINANCIALS

📣 Worldwide, inventory distortion results in an astronomical $1.1 trillion loss.

Businesses simply can’t afford to lose money through inventory issues, so you must consider ways to improve your processes and eliminate any problems. That’s where digital inventory management systems come in.

Put simply, they give you the data you need to make better-informed decisions. Plus, with additional features that enable you to allocate stock directly to jobs and alert you when you need to reorder items, you can guarantee that you won’t be spending any money that you don’t need to.

3. IMPROVE EFFICIENCY

📣 On average, companies spend approximately 16 days per year looking for misplaced paper documents.

In addition to losing paperwork, traditional administration methods are also time-consuming and usually riddled with mistakes. In contrast, you can improve the efficiency of your staff — and your business — by removing the need for pointless admin tasks.

With BigChange’s field service management system, engineers can log all vital information (such as which parts they used during an appointment) from their mobile devices. The system stores all details so your back-office team can easily keep track of your inventory and work history.

Your engineers spend less time on paperwork, which means they will have more time to complete appointments and provide a superior service to your customers.

How to set up and sort your stock, hassle free, with BigChange

Content from /blog/how-to-set-up-and-sort-your-stock-hassle-free-with-bigchange/ should be repurposed and placed into this new section

With BigChange, you can create a detailed register of assets and equipment — both for you and your clients — on one easy-to-use system.Taking care of the heavy admin, our job management system allows you to:

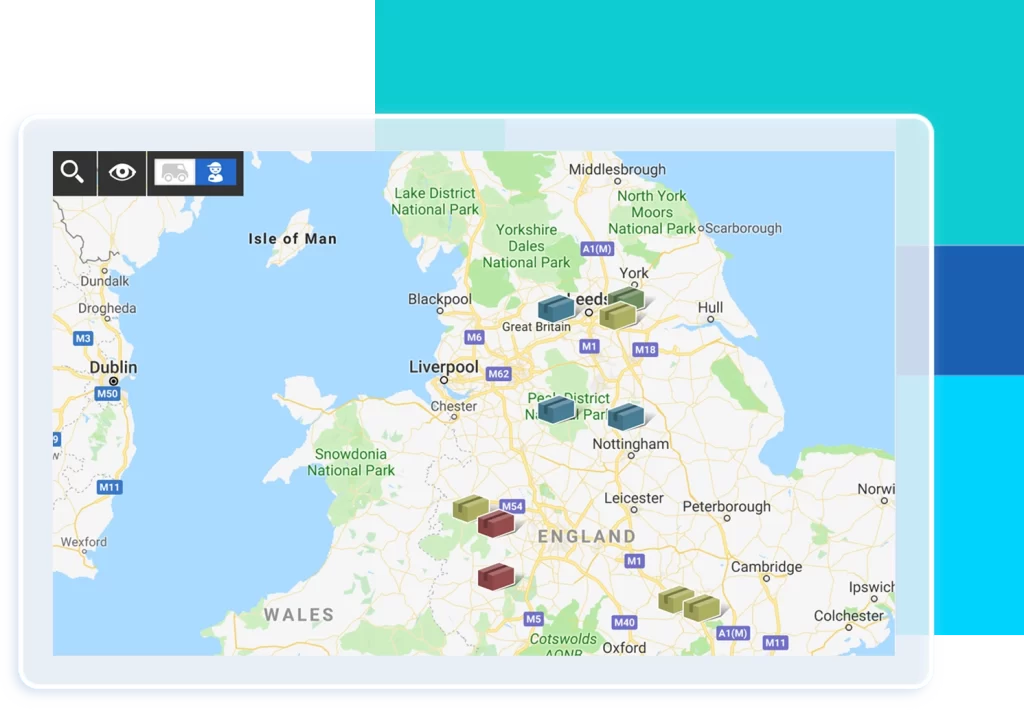

✅ Manage items across a range of locations in real-time

✅ View a complete record of your engineers’ work history

✅ Receive alerts any time your stock is running low

✅ Assign vehicles, tools and equipment directly to customers’ appointments

✅ Keep track of all assets using serial numbers, barcodes and QR codes.

✅ Add serial numbers, barcodes and QR codes to each item so you can track their whereabouts

Our team is on hand to help you set up your inventory management system in a way that makes sense for your business. Get in touch to learn more about how we can help you with onboarding and integration.

Gain a competitive advantage today with field service management software

A recent report found that only 18% of small businesses use inventory management systems.

The remaining 82% either don’t track their equipment, stock and assets, or they use manual methods that create issues further down the line.

Inventory management software is your opportunity for competitive advantage.

With the majority of SMEs (small to medium-sized businesses) missing out, your field service business has an excellent opportunity to improve operations, improve customer experiences, increase profits, and take on more projects that will help contribute to company growth.

With such a powerful tool at your fingertips, your inventory will run like clockwork, freeing up more time for you and your team to focus on more business-critical tasks.

Ready to get ahead of competitors? Get in touch and book a free consultation to see how BigChange can grow your business. You can also get helpful guides and tips delivered to your inbox by subscribing to our newsletter below.